Rakem Group Sustainability and Corporate Social Responsibility Statement

Introduction

At Rakem Group, we are dedicated to upholding the highest standards of quality, health and safety, and environmental management. As a group of companies specialising in chemical distribution and toll manufacturing of liquid and powder products, we operate grounded in the principles of responsible business practice. Our commitment to sustainability is anchored in a three-pillar approach encompassing Environmental, Social, and Governance (ESG) factors, which ensures responsible decision-making across all aspects of our operations.

Our Quality, Health, Safety, and Environmental (QHSE) team ensures adherence to global best practices, reinforced by our certifications in ISO 9001 for quality, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety. Through these standards, we strive to deliver exceptional service while safeguarding the health of our employees, customers, and the planet. Innovation is central to our endeavours, supported by IT systems that allow us to continuously improve and meet the complex demands of modern manufacturing and chemical distribution. Our company values of Fun, Family, Integrity, Innovation, and Friendliness are reflected in our approach to QHSE and IT.

Our Approach

Rakem Group is committed to operating sustainably and responsibly. We recognise that our activities have an impact on the environment, society, and economy, and we strive to minimise negative effects while maximising positive contributions. We aim to create value for our customers, suppliers, employees, shareholders, and communities while respecting environmental protection, human rights, and ethical conduct.

To this end, we adopt a three-pillar approach to sustainability and corporate social responsibility, integrating ESG factors into our decision-making processes, risk management, and performance measurement. We report regularly and transparently on our ESG performance and progress in accordance with the Global Reporting Initiative (GRI) standards and the United Nations Global Compact (UNGC) principles.

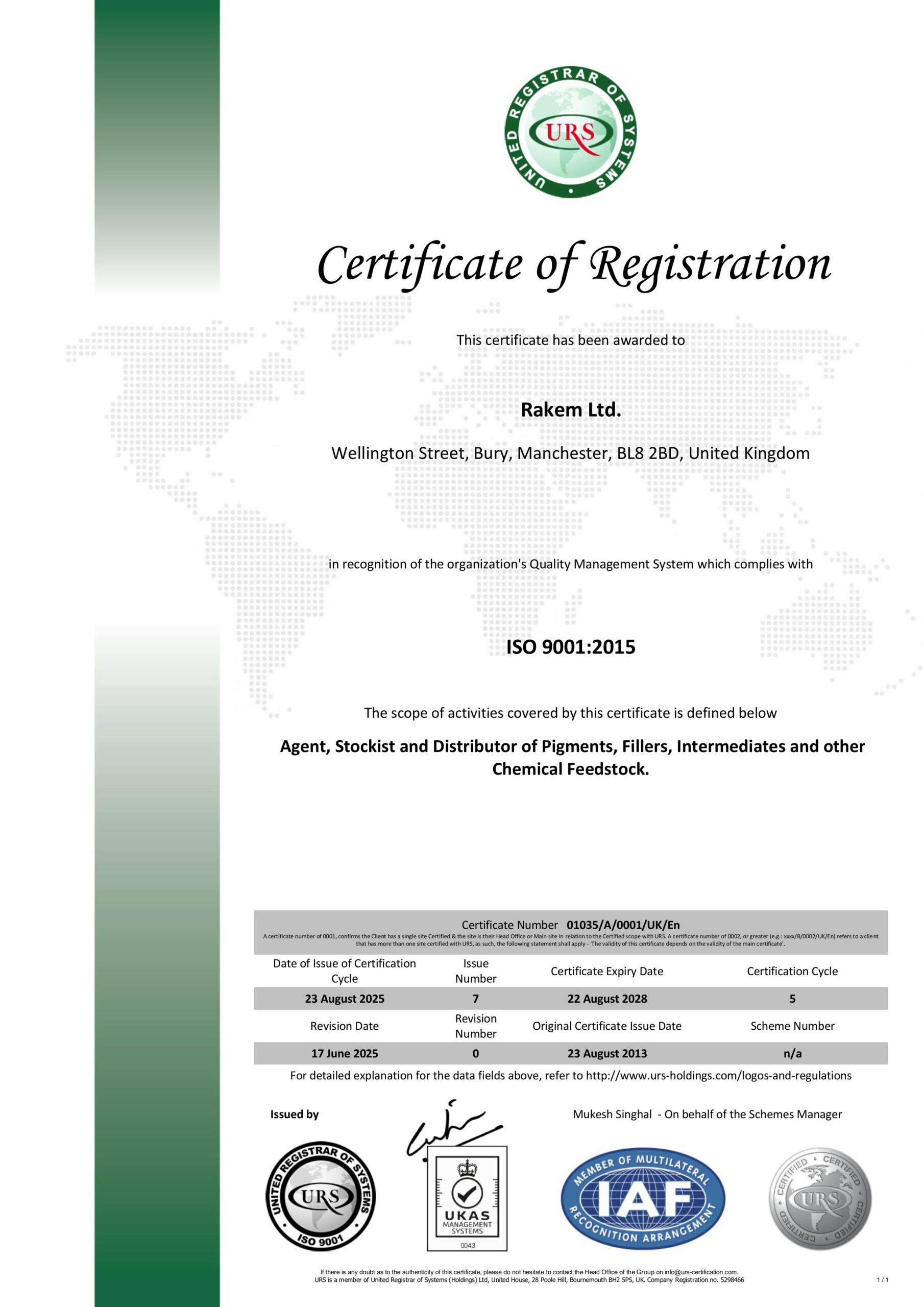

Quality Management (ISO 9001)

Our ISO 9001 certification assures that we uphold the highest quality standards across all operations, from chemical distribution to toll manufacturing. A robust Quality Management System (QMS) enables us to consistently meet customer specifications and regulatory requirements:

- Quality Assurance in Chemical Distribution: Each batch of chemicals is carefully tracked and controlled to ensure it meets safety and quality standards, maintaining detailed records for full traceability and compliance.

- Toll Manufacturing Process Control: Regular audits and reviews of production protocols are conducted by our QHSE team to ensure compliance with ISO 9001 standards.

- Innovation through IT: Our IT systems enable monitoring of product quality and tracking of batch performance, allowing for quick responses to any deviations.

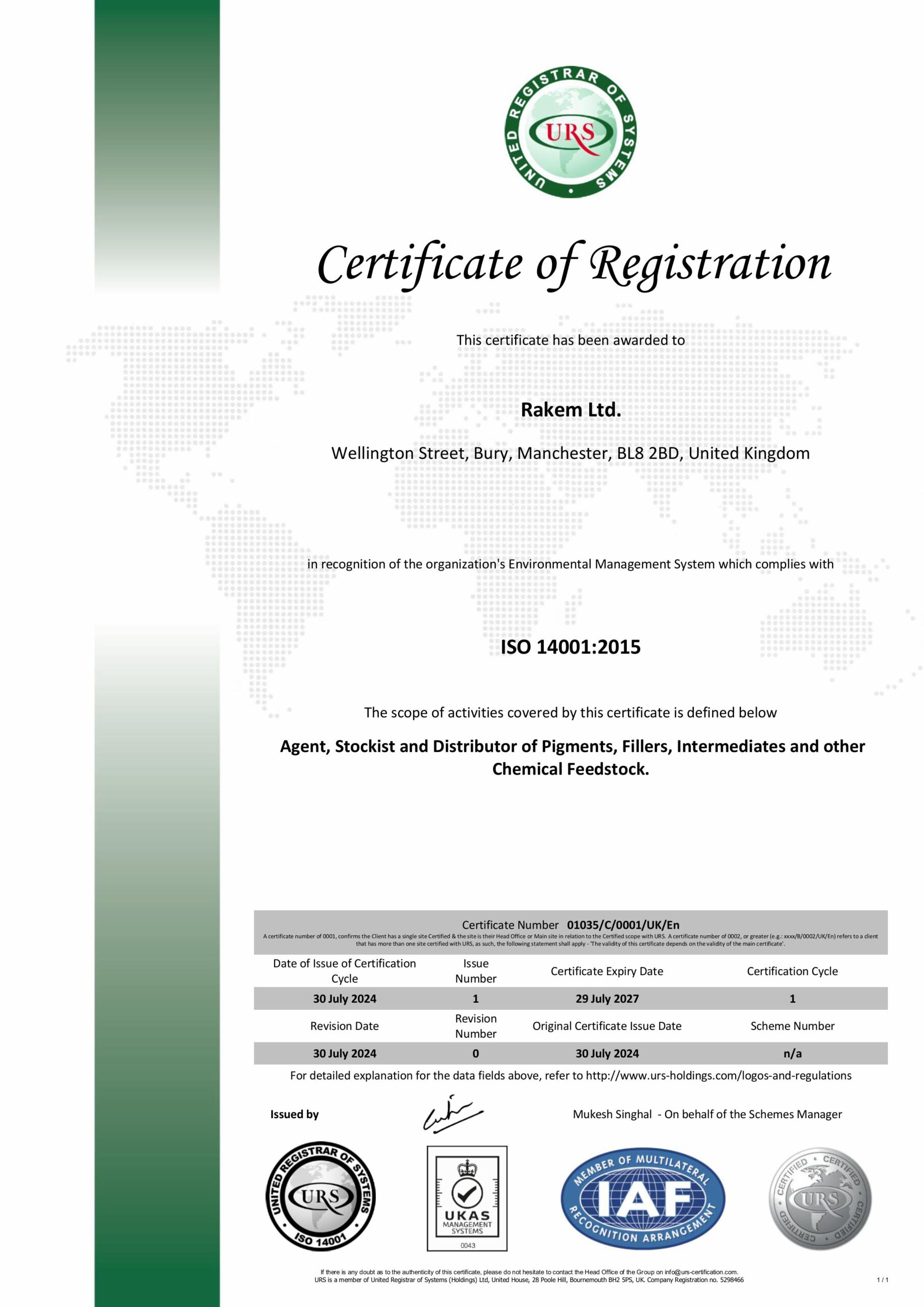

Environmental Management (ISO 14001)

As a responsible chemical distributor and manufacturer, we are committed to reducing our environmental impact through ISO 14001 certification:

- Sustainable Manufacturing Initiatives: We have implemented energy-efficient production processes to reduce emissions and waste. Resource efficiency is monitored in our manufacturing facilities, and all waste produced is offset to carbon neutral, with a target to achieve net zero by 2030.

- Chemical Handling & Distribution: Safe storage, handling, and transportation of chemicals are prioritised, with systems tracking inventory levels to reduce wastage.

- Green IT Solutions: IT systems manage sustainability data, supporting our environmental goals and reducing our operational footprint through paperless initiatives.

- Renewable Resources: We are dedicated to promoting renewable and eco-friendly products, exceeding environmental regulations whenever possible.

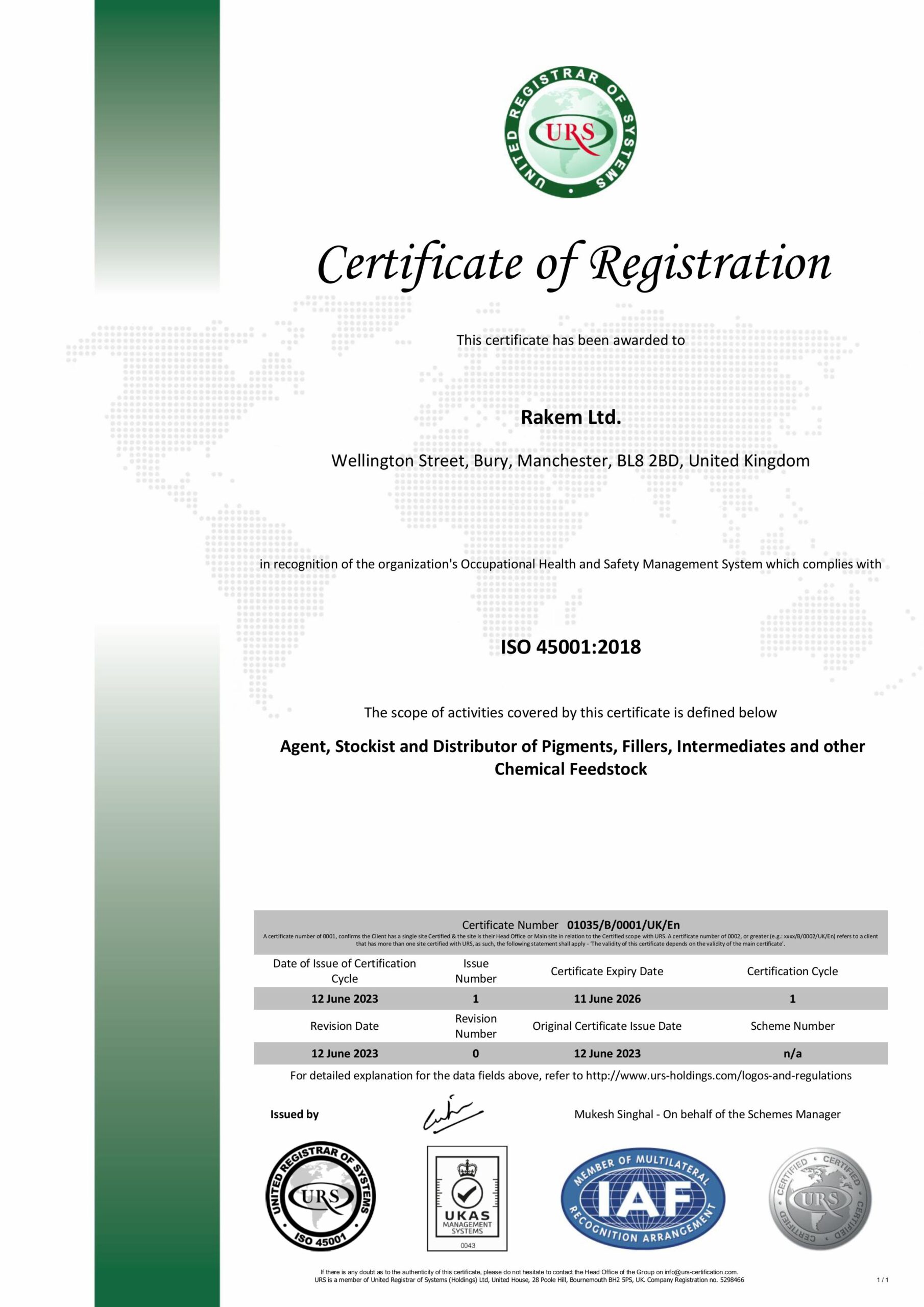

Health & Safety Management (ISO 45001)

ISO 45001 certification underpins our commitment to health and safety in the workplace, particularly given the risks involved in chemical handling and manufacturing:

- Workplace Safety in Manufacturing: Our QHSE team assists managers in risk assessments and safety audits, ensuring compliance with ISO 45001.

- Incident Tracking and Response: IT systems enable real-time tracking of safety incidents and near-misses, facilitating swift responses to minimise risks.

- Safe Distribution Practices: Safety during chemical distribution is paramount, with systems ensuring compliance with hazardous material regulations.

Corporate Social Responsibility (CSR) Achievements

Our CSR philosophy is rooted in our values of Family, Integrity, and Friendliness, focusing on making a positive impact on our stakeholders:

- Community Engagement: We actively participate in local community initiatives, offering financial support and encouraging employee volunteering.

- Environmental Projects: Our QHSE team drives projects aimed at reducing our carbon footprint through energy-efficient practices and recycling initiatives.

- Ethical Practices: Integrity is central to our operations, maintained through transparent supply chains and monitoring supplier performance with IT systems.

Silver Ecovadis Medal

Our commitment to sustainability and corporate responsibility has been recognised with the prestigious Ecovadis Silver Medal awarded to our company Maker. This reflects our dedication to environmental sustainability, human rights, ethics, and sustainable procurement practices.

We are committed to continuous improvement and innovation in our sustainability and corporate social responsibility performance, welcoming feedback from stakeholders and seeking collaboration to address the challenges and opportunities within our industry. By working together, we believe we can create a more sustainable and responsible future for all.

IMS Case Studies

1. Accident Reduction: Since the implementation of our ISO 45001 Health and Safety Management System, we have consistently observed a reduction in incident frequency. The combination of our commitment to health and safety through the management system and the use of our internal QHSE software has enabled us to focus our staff on near-miss and hazard reporting before these issues escalate into incidents.

2. Resource Allocation: Our management’s commitment to health and safety is clearly demonstrated by the allocation of resources dedicated to keeping employees safe. In recent years, the company has invested in the development of a QHSE department and has acquired equipment for production that significantly reduces risk. This includes our state-of-the-art Local Exhaust Ventilation (LEV) system, TAWI crane systems that eliminate manual handling, and high-speed shutter doors that facilitate seamless movement, temperature control, and ventilation.

3. Safety Climate Survey: Our ongoing commitment to improving health and safety would hold little value without the satisfaction of our employees. Therefore, we continually consult them during our development process. As part of this consultation, we conduct an annual HSE Safety Climate Survey, which has shown year-on-year improvement. Last year, we achieved a 12.8% increase from the previous year and scored better than 95% of organisations in our comparison group, which consists of 130 organisations.

Certifications