Lithium carbonate and lithium hydroxide are widely used across industrial sectors, each offering distinct advantages. Lithium carbonate is often the preferred choice due to its stability, cost-effectiveness, and versatility. At Cemkem, we provide innovative solutions designed to meet the specific needs of manufacturers in various industries, ensuring access to high-quality materials for diverse applications.

This article breaks down the key differences between these two compounds and emphasises how our tailored offerings can align with the needs of various sectors.

Chemical Composition

Lithium carbonate (Li₂CO₃) is a stable, well-established compound composed of lithium, carbon, and oxygen. Its structure provides predictable performance in industrial settings, making it a reliable material for sectors requiring long-term stability. In contrast, lithium hydroxide (LiOH) is more reactive and alkaline, making it suitable for select high-performance applications, particularly in battery cathodes.

For industries that prioritise consistency and controlled reactivity, lithium carbonate represents a dependable option. Cemkem works closely with manufacturers to provide high-quality formulations for applications where stability is key.

Solubility

The solubility of a compound determines how it behaves in industrial applications. Lithium carbonate exhibits lower solubility in water, allowing for controlled reactions that make it valuable in glass, ceramics, and energy storage applications. Lithium hydroxide, conversely, dissolves more readily, leading to rapid reactions that require careful handling.

Manufacturers seeking a lithium source that balances solubility with stability often turn to lithium carbonate. Cemkem supplies effective formulations to industries where predictable reaction rates are essential for efficient production.

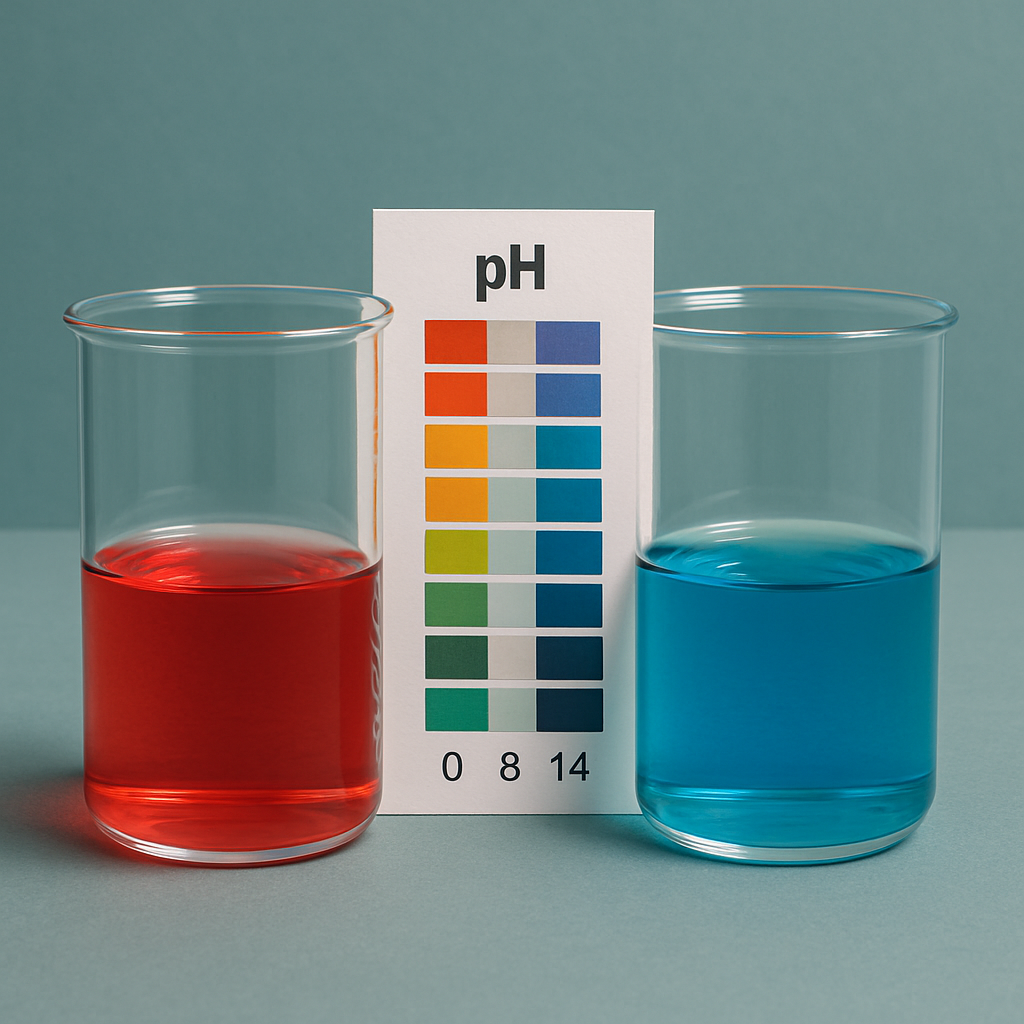

pH Levels

Lithium hydroxide is highly alkaline, with a pH above 12, making it effective for acid neutralisation but requiring careful handling. Lithium carbonate, with a pH around 8-10, offers a more balanced alternative, reducing risks in processes that demand chemical stability.

This makes lithium carbonate an ideal choice for various industrial applications. This is why Cemkem offers innovative solutions designed to meet the critical safety and control standards necessary for successful operations.

Thermal Stability

When exposed to high temperatures, lithium carbonate remains stable, making it well-suited for use in ceramics, glass production, and energy storage applications. Lithium hydroxide, however, decomposes more readily under heat, limiting its use in processes that require sustained high temperatures.

For industries that require temperature-resistant formulations, Cemkem ensures that manufacturers can rely on quality and performance for processes under extreme conditions.

Industrial Applications

Lithium carbonate plays a crucial role in multiple industries:

- Glass & Ceramics – Enhances durability and thermal properties.

- Batteries – Used in lithium-ion battery precursors.

- Pharmaceuticals – Found in specific medical formulations.

While lithium hydroxide is favoured in some battery applications, lithium carbonate’s versatility and cost-effectiveness make it an essential material across various sectors. Cemkem works with manufacturers to ensure they have a steady, high-quality formulation for their specific needs.

Reaction with Acids

Lithium carbonate reacts with acids by releasing carbon dioxide, making it suitable for controlled chemical synthesis. Lithium hydroxide, on the other hand, neutralises acids more aggressively, which can be useful in wastewater treatment but requires stricter handling protocols.

For industries requiring precision in acid-based reactions, our specialised materials provide effective, manageable solutions that meet stringent requirements.

Hygroscopic Nature

One of the advantages of lithium carbonate is its lower hygroscopicity, meaning it absorbs less moisture from the air compared to lithium hydroxide. This simplifies storage and transportation while reducing the risk of degradation. Lithium hydroxide, being highly hygroscopic, requires airtight storage and handling to prevent instability.

For manufacturers prioritising logistical efficiency and product integrity, Cemkem provides products that meet rigorous storage and quality standards.

Toxicity

When handled properly, lithium carbonate has low toxicity, though exposure should be minimised to prevent irritation. Lithium hydroxide, due to its stronger alkalinity, carries higher toxicity risks, necessitating strict safety protocols, including protective equipment and ventilation.

For industries where worker safety is a priority, lithium carbonate offers a lower-risk alternative. Cemkem supplies the ideal formulation to manufacturers seeking safe, high-performance lithium compounds.

In summary, while lithium carbonate and lithium hydroxide serve distinct purposes, lithium carbonate stands out for its stability, ease of handling, and cost-effectiveness. As industries evolve, Cemkem is committed to providing innovative solutions that meet the growing demand for reliable lithium compounds. Contact us today to learn how we can support your production processes.

For expert advice and reliable supply solutions, reach out to Cemkem and discover how our specialised products can enhance your production processes.