For manufacturers and industrial buyers alike, picking the right paper type often shapes more than just the end product—it can shift costs, performance, and even the brand perception of what gets printed. That is, knowing whether to use coated or uncoated paper isn’t a small detail. It’s more like a quiet decision with loud consequences.

What is Coated Paper?

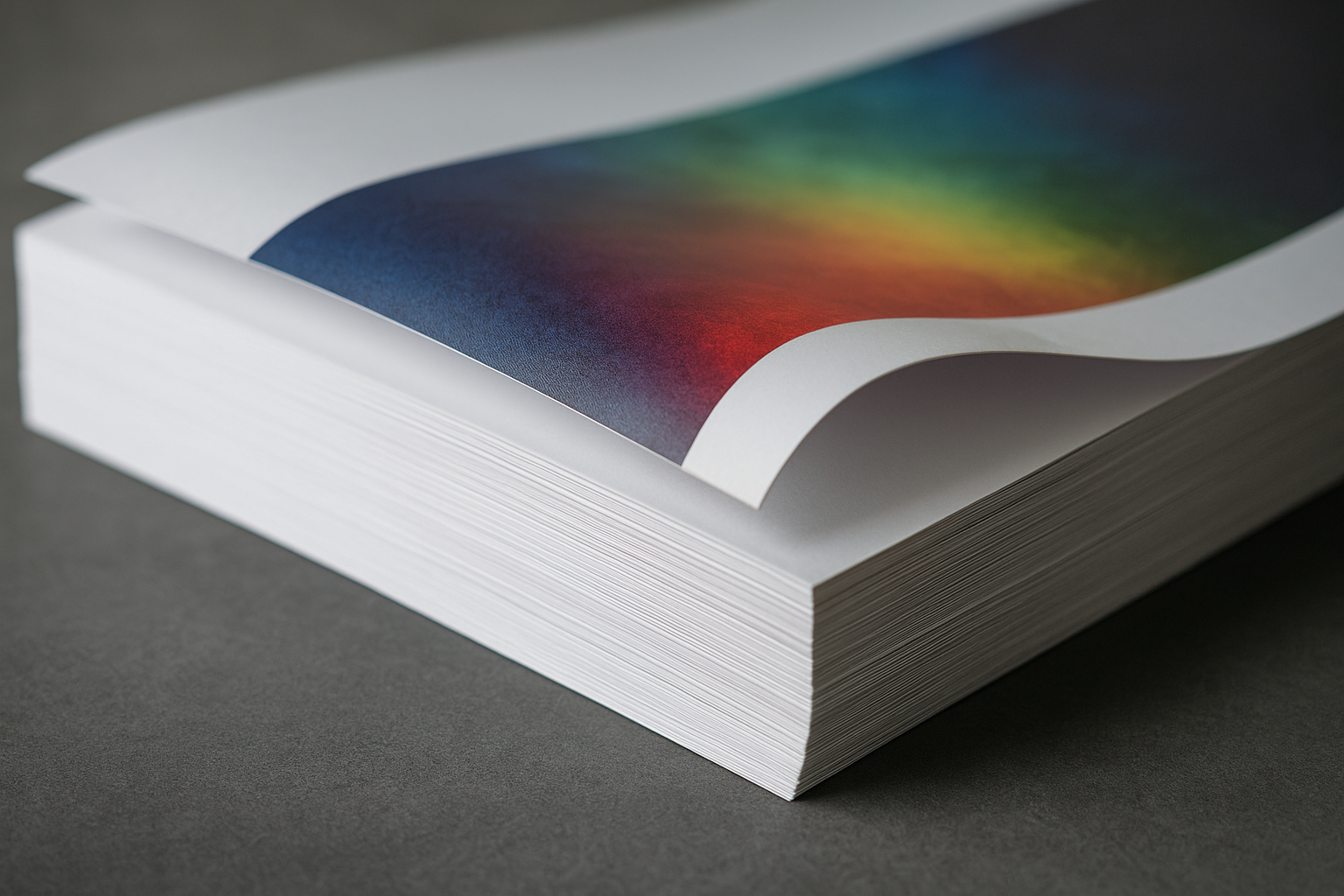

Coated paper is, put simply, paper that’s had a surface treatment—usually a clay or polymer-based mixture—that fills in the natural pits and fibres. This paper coating results in a paper that feels smoother to the touch, reflects light in a more controlled way, and supports high-definition printing.

The benefits? Well, they’re easy to spot. Images appear sharper, colours pop more, and smudging becomes less of a worry. For any application where detail matters—packaging, marketing collateral, branded inserts—coated paper tends to be the preferred choice.

So, if you’re aiming for consistency and clarity, especially under high-speed printing or in bulk production, then this paper type usually holds up better.

What is Uncoated Paper?

Uncoated paper skips the surface treatment entirely. That’s what gives it its open texture—slightly rough, more absorbent, and more tactile. Think of it as paper in its less processed form.

It’s often used for things like stationery, books, manuals, or anything that needs to be written on, rather than just printed. Because there’s no coating, ink sinks in a bit more, which gives it a softer, less glossy appearance. This can actually work in your favour if the aim is readability and a natural feel.

Plus, it’s often the go-to for industrial uses where surface friction or static resistance might be relevant factors. It’s not just a cheaper option—it’s a deliberate one for the right scenarios.

Surface Smoothness and Print Quality

Let’s look at the key contrasts in feel and function:

Feature | Coated Paper | Uncoated Paper |

Surface Feel | Smooth, sleek | Slightly rough, natural |

Print Finish | Glossy or matte, depending on the coating | Naturally non-glossy |

Colour Definition | High saturation and sharpness | Softer, less vibrant |

Best For | Packaging, brochures, labels | Stationery, manuals, forms |

So, smoother surfaces reduce how much ink spreads. This tight control keeps the text crisp and the colours well-defined. In short, coated paper often looks cleaner and more polished. That’s why, for premium branding or technical illustrations, coated stock tends to win.

Ink Absorption and Holdout

Here’s where things get slightly technical, but useful. Coated paper tends to hold ink on its surface, while uncoated paper soaks it up. This holdout matters—a lot.

- Coated Paper

- The ink stays near the top.

- It dries faster because less ink is absorbed into the surface.

- Sharp lines and bold tones stay put.

- Uncoated Paper

- The ink sinks in more.

- It takes a little longer to dry.

- The result is a more muted, natural print.

If your print spec demands clean lines and dense colour, then coated paper’s ink holdout gives you the upper hand. But if you’re looking for something easier on the eye, or a material that handles pen ink without bleeding, uncoated might be the better fit.

Chemical Resistance and Durability

Let’s be honest—paper doesn’t always have an easy ride. Packaging might sit in humid storage. Labels face splash zones. Manuals get handled with oily hands. So, how does each type perform under pressure?

Coated paper tends to hold up better in chemical-prone or high-moisture environments. That layer of coating adds a bit of resistance, not waterproofing exactly, but definitely a buffer against quick degradation.

Uncoated paper, by contrast, absorbs not just ink but moisture and contaminants too. Over time, this can make it warp or wear faster, particularly in exposed settings.

So, when durability and chemical resistance are priorities, like in outer packaging, food contact layers, or industrial labels, coated variants are more reliable.

Environmental Impact

This is the bit that’s shifting most. Traditionally, coated papers weren’t always the greenest option. The added coatings could include synthetic components that made recycling trickier. But now, newer formulations—like bio-based or water-dispersible coatings—are changing that.

Uncoated paper is often seen as more environmentally friendly. And in some cases, it is. No coating means fewer processing stages and easier recycling.

But context is key. If your coated paper improves performance, reduces waste, or lasts longer in use, then it can still be a more sustainable choice. Especially if sourced from a supplier of sustainable paper coating solutions.

Where to Find Paper Coating Chemicals

If you’re weighing up options for performance or environmental goals, you’ll want a partner who understands both. Rakem doesn’t just supply paper coating chemicals. We manufacture coatings and provide fillers, extenders, dispersants, and pigments, working alongside manufacturers to solve the specific challenges they face.

From adjusting gloss levels to increasing print adhesion, our coatings and raw materials are developed to meet real industrial needs, not just tick boxes. Whether you’re reformulating or improving consistency, our team’s ready to advise.

Contact us for practical guidance, technical specs, or help with coated and uncoated paper transitions.